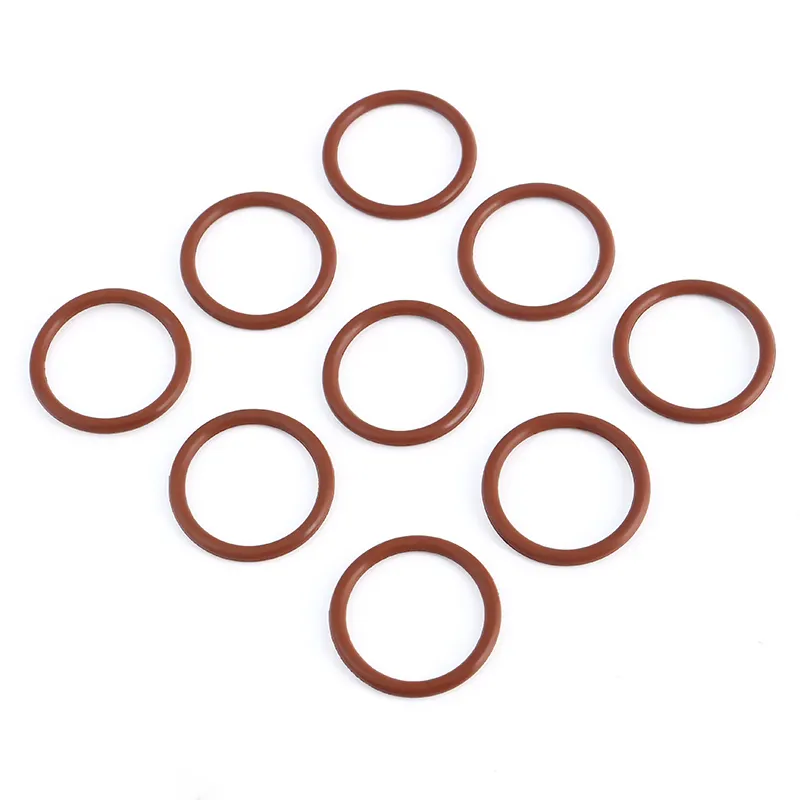

Custom Rubber O Ring Wholesale Price

Product Overview

- The product is a range of rubber O rings available in different materials including Nitrile, Fluorine, Silicone, EPDM, HNBR, Neoprene, and Fluorosilicone Rubber.

- The materials have different temperature ranges, hardness levels, and characteristics such as oil resistance, high temperature resistance, and resistance to specific solvents.

- The O rings are commonly used in various industries including automotive, aviation, machinery, chemical, and household appliances.

Product Features

- Each material has specific temperature ranges and characteristics tailored to different applications.

- The O rings are available in different Shore A hardness levels for customization.

- The materials offer properties such as oil resistance, high temperature resistance, chemical resistance, and corrosion resistance.

Product Value

- The rubber O rings offer high-quality sealing solutions for various industries.

- They provide reliable performance in different operating conditions due to their specific material characteristics.

- Customization options for hardness levels allow for tailored solutions to meet specific application requirements.

Product Advantages

- The O rings are made from materials known for their durability, elasticity, and resistance to various environmental factors.

- They provide excellent sealing performance for fuel tanks, lubricating oil tanks, hydraulic systems, and other fluid media applications.

- The O rings offer good compression and deformation resistance, making them suitable for demanding industrial environments.

Application Scenarios

- The rubber O rings are commonly used in key parts of aviation, automotive, machinery, and chemical industries.

- They are suitable for sealing or rubber parts in household appliances, food machinery, and products in contact with the human body.

- The O rings are ideal for use in transformers, switch cabinets, and other electrical and mechanical equipment requiring reliable sealing solutions.