Enhance Your Bonding Strength With 3M Adhesive Rubber Pads

Looking for ways to enhance the bonding strength of your products or projects? Look no further than 3M adhesive rubber pads. These innovative pads offer a reliable and durable solution for a wide range of bonding applications. In this article, we will explore the benefits and uses of 3M adhesive rubber pads, and how they can help improve the strength and longevity of your bonding projects. Whether you're a DIY enthusiast or a professional in need of a reliable bonding solution, 3M adhesive rubber pads are worth considering. Read on to learn more!

- Understanding the Benefits of 3M Adhesive Rubber Pads

When it comes to adhesive solutions, 3M is a name that is trusted and revered by professionals and DIY enthusiasts alike. One of 3M's most versatile and effective products is their adhesive rubber pads. These pads have a wide range of applications and offer numerous benefits when it comes to bonding strength. In this article, we will delve deeper into the benefits of 3M adhesive rubber pads and how they can enhance your bonding strength in various applications.

One of the key benefits of 3M adhesive rubber pads is their exceptional durability. These pads are designed to withstand harsh environmental conditions, including extreme temperatures, moisture, and UV exposure. This makes them an ideal choice for outdoor applications such as mounting solar panels, outdoor signage, and outdoor furniture. Their ability to maintain their adhesive strength in challenging environments sets them apart from other adhesive solutions.

Additionally, 3M adhesive rubber pads offer excellent shock absorption and vibration dampening properties. This makes them an excellent choice for use in automotive and electronic applications. The ability of these pads to absorb and dissipate energy helps to protect delicate components and sensitive equipment from damage caused by vibration and impact. Whether it's securing electronic components in a vehicle or mounting delicate sensors, 3M adhesive rubber pads provide the necessary cushioning and protection.

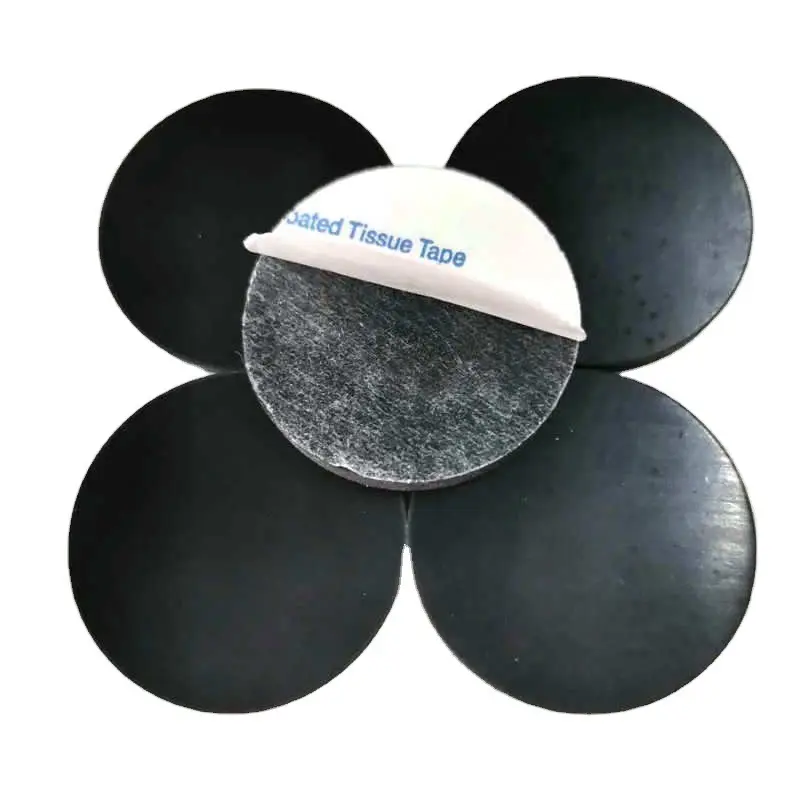

Furthermore, 3M adhesive rubber pads are known for their versatility and ease of use. These pads are available in various shapes, sizes, and thicknesses, making it easy to find the perfect solution for your specific bonding requirements. Whether you need to bond a small electronic component or secure a large object, there is a 3M adhesive rubber pad that will meet your needs. Their easy-to-use peel-and-stick application makes them an ideal choice for both professionals and DIY enthusiasts.

In addition to their durability, shock absorption, and versatility, 3M adhesive rubber pads also offer excellent adhesion to a wide range of substrates. Whether you are bonding metal, plastic, glass, or wood, these pads provide a strong and reliable bond. This makes them an excellent choice for a variety of applications, including industrial, commercial, and residential projects.

In conclusion, 3M adhesive rubber pads are an exceptional choice for enhancing bonding strength in a wide range of applications. Their durability, shock absorption, versatility, and strong adhesion to various substrates make them a go-to solution for professionals and DIY enthusiasts alike. Whether you are looking to secure outdoor signage, protect delicate electronic components, or mount objects in challenging environments, 3M adhesive rubber pads are a reliable and effective choice. Consider adding these pads to your adhesive solutions toolkit for optimal bonding strength and peace of mind.

- Getting Started: How to Apply 3M Adhesive Rubber Pads

If you’re looking to enhance your bonding strength, 3M Adhesive Rubber Pads are an excellent solution. These pads are designed to provide a strong and reliable bond on a variety of surfaces, making them perfect for a wide range of applications. In this article, we’ll provide a detailed guide on how to apply 3M Adhesive Rubber Pads, giving you the tools you need to achieve the best results.

Before you begin applying the adhesive rubber pads, it’s important to ensure that the surface you’re working with is clean and free of any dust, dirt, or debris. This will help to ensure that the pads adhere properly and provide a strong bond. If the surface is dirty or greasy, it’s a good idea to clean it with a mild detergent and warm water before proceeding.

Next, carefully remove the adhesive backing from the rubber pads. It’s important to handle the pads carefully to avoid touching the adhesive, as this can affect its ability to bond to the surface. Once the backing is removed, carefully place the pad onto the desired surface, applying firm and even pressure to ensure a secure bond.

When applying the pads, it’s important to consider the specific requirements of your application. For example, if you’re using the pads to mount a heavy object, it may be necessary to use multiple pads to provide the necessary support. Additionally, if the surface is uneven or rough, you may need to consider using a thicker or more durable pad to ensure a strong bond.

In some cases, it may be necessary to trim the pads to the desired size or shape. This can easily be done using a pair of scissors or a sharp knife, taking care to ensure that the edges are smooth and even. Once the pads are in place, it’s important to allow them to set and cure for the recommended amount of time. This will help to ensure that the bond is strong and durable.

In addition to providing a strong bond, 3M Adhesive Rubber Pads also offer a number of other benefits. For example, they can help to dampen vibration and reduce noise, making them ideal for use in a variety of industrial and commercial applications. Additionally, the pads are resistant to temperature and moisture, ensuring that they provide a reliable bond even in challenging environments.

In conclusion, 3M Adhesive Rubber Pads are an excellent solution for enhancing bonding strength in a wide range of applications. By following the steps outlined in this article, you can achieve a strong and reliable bond that will stand the test of time. Whether you’re mounting a heavy object or looking to reduce noise and vibration, these pads offer a versatile and effective solution for a variety of bonding needs.

- Tips for Achieving Maximum Bonding Strength

When it comes to achieving maximum bonding strength, 3M adhesive rubber pads are the way to go. These innovative pads are designed to provide a strong and reliable bond, making them ideal for a wide range of applications. Whether you're working on a DIY project at home or tackling a challenging industrial task, 3M adhesive rubber pads are sure to meet your needs.

One of the key factors that contribute to the superior bonding strength of 3M adhesive rubber pads is their advanced formulation. These pads are made with high-quality materials that are engineered to deliver exceptional performance. The adhesive used in these pads is specifically designed to create a strong and lasting bond, ensuring that your project stays secure and in place.

In addition to their superior formulation, 3M adhesive rubber pads are also designed to provide excellent adhesion to a variety of surfaces. Whether you're working with metal, wood, plastic, or another material, these pads are capable of forming a reliable bond that will hold up under tough conditions. This versatility makes 3M adhesive rubber pads an ideal choice for a wide range of applications, from automotive repairs to household projects.

To ensure that you achieve maximum bonding strength with 3M adhesive rubber pads, it's important to follow a few key tips. First and foremost, it's essential to thoroughly clean and prepare the bonding surface before applying the pads. Any dirt, oil, or debris on the surface can interfere with the adhesive bond, so be sure to clean the surface carefully and allow it to dry completely before applying the pads.

Once the surface is clean and dry, it's time to apply the 3M adhesive rubber pads. When doing so, be sure to apply firm and even pressure to ensure that the pads bond securely to the surface. It's also important to allow the adhesive to cure for the recommended amount of time before subjecting the bond to any significant stress or strain.

In addition to proper surface preparation and application techniques, it's also important to consider the environmental conditions in which the bonding will occur. Temperature, humidity, and other factors can all impact the performance of the adhesive, so be sure to take these variables into account when working with 3M adhesive rubber pads.

Finally, it's essential to choose the right type of 3M adhesive rubber pads for your specific application. These pads are available in a variety of formulations and sizes, so be sure to select the option that best matches your needs. Whether you require a high-strength adhesive for a demanding industrial task or a more flexible and versatile option for a home improvement project, 3M has the right adhesive rubber pad for you.

In conclusion, achieving maximum bonding strength with 3M adhesive rubber pads is easy when you follow the right tips and techniques. With their advanced formulation, excellent adhesion, and versatile options, these pads are sure to provide the strong and reliable bond you need for your next project. So, why settle for anything less? Upgrade your bonding strength today with 3M adhesive rubber pads.

- Long-lasting Durability: Why 3M Adhesive Rubber Pads Stand Out

When it comes to bonding strength, 3M adhesive rubber pads are a cut above the rest. These innovative pads are designed to provide long-lasting durability, making them stand out in the world of adhesive products.

One of the key reasons why 3M adhesive rubber pads excel in durability is their high-quality construction. These pads are made with a special blend of rubber and adhesive materials that are engineered to withstand the test of time. Unlike traditional adhesive products, 3M adhesive rubber pads are built to resist wear and tear, ensuring that they maintain their bonding strength for an extended period of time.

In addition to their robust construction, 3M adhesive rubber pads are also designed to withstand harsh environmental conditions. Whether it's extreme temperatures, moisture, or UV exposure, these pads are formulated to remain intact and provide reliable bonding strength. This makes them an ideal solution for a wide range of applications, from industrial equipment to outdoor signage.

Furthermore, 3M adhesive rubber pads offer a high level of versatility, making them suitable for various bonding applications. Whether you need to mount a heavy-duty object or secure a delicate electronic component, these pads can provide the reliable adhesion you need. Their flexibility and adaptability ensure that they can meet the diverse needs of different industries and projects.

Another factor that sets 3M adhesive rubber pads apart is their ease of use. These pads are designed to be user-friendly, allowing for quick and hassle-free application. Simply peel off the backing and press the pad onto the surface to create a secure bond. This simplicity not only saves time and effort but also ensures a consistent and reliable result every time.

In addition to their durability, versatility, and ease of use, 3M adhesive rubber pads are also backed by the reputable 3M brand. With a long-standing reputation for quality and innovation, 3M products are trusted by professionals and consumers worldwide. This legacy of excellence gives users peace of mind, knowing that they are investing in a reliable and high-performance adhesive solution.

Overall, 3M adhesive rubber pads stand out for their long-lasting durability, making them the go-to choice for bonding strength. With their high-quality construction, resistance to environmental factors, versatility, ease of use, and the backing of a reputable brand, these pads offer a superior adhesive solution for a wide range of applications. Whether you're in the manufacturing, construction, automotive, or electronics industry, 3M adhesive rubber pads can enhance your bonding strength and ensure a reliable and lasting bond.

- Creative Applications for 3M Adhesive Rubber Pads

When it comes to securing objects in place, 3M adhesive rubber pads have proven to be a go-to solution for many industries. These innovative pads offer a wide range of creative applications that can improve bonding strength in various scenarios. From industrial machinery to household appliances, 3M adhesive rubber pads provide a reliable and long-lasting solution for secure bonding.

One of the key advantages of 3M adhesive rubber pads is their versatility. These pads come in various shapes and sizes, making them suitable for a wide range of applications. Whether you need to secure a small electronic component or a large piece of industrial equipment, there is a 3M adhesive rubber pad that can meet your specific needs. This versatility allows for creative and customized solutions for bonding strength.

In the automotive industry, 3M adhesive rubber pads are commonly used to secure various components in place. These pads provide a strong bond that can withstand the vibrations and impact that come with driving. Whether it's securing a GPS unit to the dashboard or mounting a camera to the exterior of a vehicle, 3M adhesive rubber pads offer a reliable solution that can withstand the rigors of the road.

In the world of consumer electronics, 3M adhesive rubber pads are used to secure components within devices such as smartphones, tablets, and laptops. These pads provide a secure bond that can withstand the everyday wear and tear that comes with regular use. Additionally, 3M adhesive rubber pads can help to dampen vibrations, reducing the risk of damage to delicate electronic components.

In the manufacturing industry, 3M adhesive rubber pads are utilized to secure machinery and equipment in place. These pads offer a strong and reliable bond that can withstand the harsh conditions of industrial environments. Whether it's securing a control panel to a piece of equipment or mounting a sensor to a production line, 3M adhesive rubber pads provide a durable solution for bonding strength.

In addition to their bonding strength, 3M adhesive rubber pads also offer the benefit of easy installation. These pads come with a pressure-sensitive adhesive backing, allowing for quick and hassle-free application. This ease of installation reduces downtime and allows for efficient use of time and resources in various industries.

Furthermore, 3M adhesive rubber pads are designed to provide long-lasting performance. These pads are resistant to aging, ensuring that they maintain their bonding strength over time. This reliability makes 3M adhesive rubber pads a cost-effective solution for securing objects in place, as they require minimal maintenance and replacement.

In conclusion, 3M adhesive rubber pads offer a range of creative applications that can enhance bonding strength in various industries. Their versatility, durability, and ease of installation make them a reliable solution for securing objects in place. Whether it's in the automotive industry, consumer electronics, or manufacturing, 3M adhesive rubber pads provide a secure and long-lasting bond that meets the specific needs of various applications. With their proven performance, it's no wonder why 3M adhesive rubber pads are a popular choice for enhancing bonding strength in countless scenarios.

Conclusion

In conclusion, 3M adhesive rubber pads offer a superior bonding strength that can enhance the durability and longevity of your projects. Whether you are working on DIY home improvement projects or industrial applications, these adhesive pads provide a reliable and long-lasting bonding solution. With their versatility and effectiveness, 3M adhesive rubber pads are a valuable addition to any toolkit. So, whether you’re looking to enhance the performance of your furniture, electronics, or other materials, consider using 3M adhesive rubber pads to achieve a strong and lasting bond. With their proven track record of excellence, you can trust that 3M adhesive rubber pads will deliver the results you need.